ABOUT WOODSUN

Guangdong WoodSun Housewares Co., Ltd. was established in 2005. We are global leader in manufacturing vacuum insulated stainless-steel and reusable plastic drinking vessels /accessories in highly modernized factories. One of stainless steel factories devotes to high-level quality standard for current customers as Starbucks and Xiaomi with 200 employees and 21,000㎡. And the other one is specialized for middle-level customers with huge quantity, such as Walmart, Costco, Target store and Starbucks, etc. There are over 700 employees in the factory and it covers 46,000㎡. Also one factory for plastic production specifically is with 200 employees and 18,000㎡.

Our daily production capacity is 100,000 pieces. Besides, we have advanced finishing capabilities in the industry with 2 production lines for automated spray painting and automated UV painting. For achieving the wide variety of finishes, there are also HD automated water transfer machines as well as a fully automatic silk screen printing machine which enables us to achieve designs with up to 6 colors printing with laser precision. With these technical abilities, we are able to apply over 60 kinds of unique finishes including air transfers which gives us the ultimate flexibility to customize our products for all kinds of our valued customers’ needs and requests.

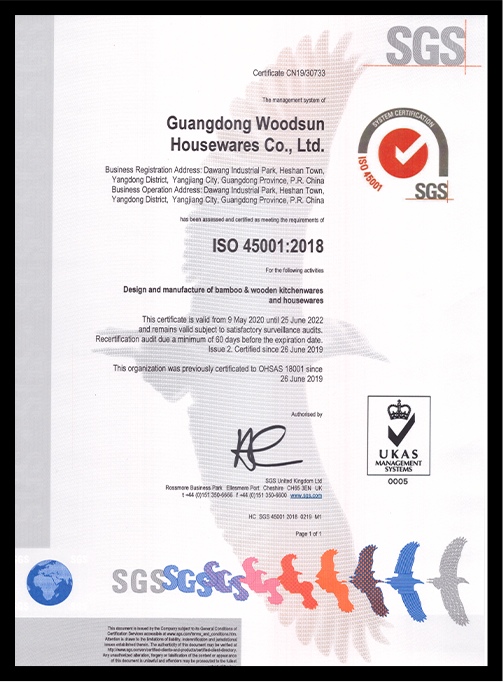

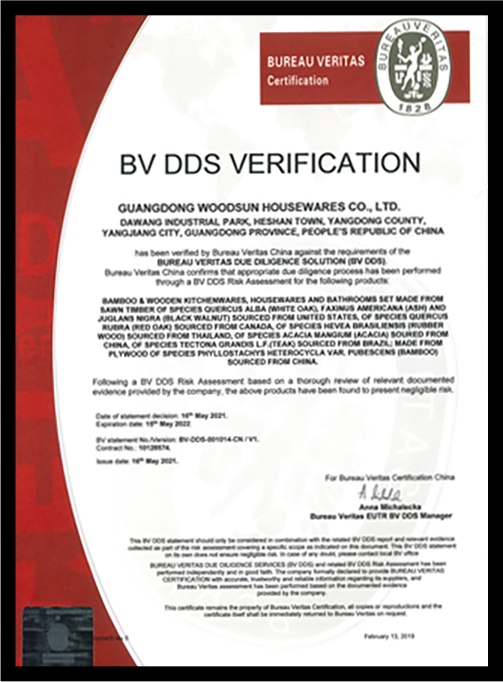

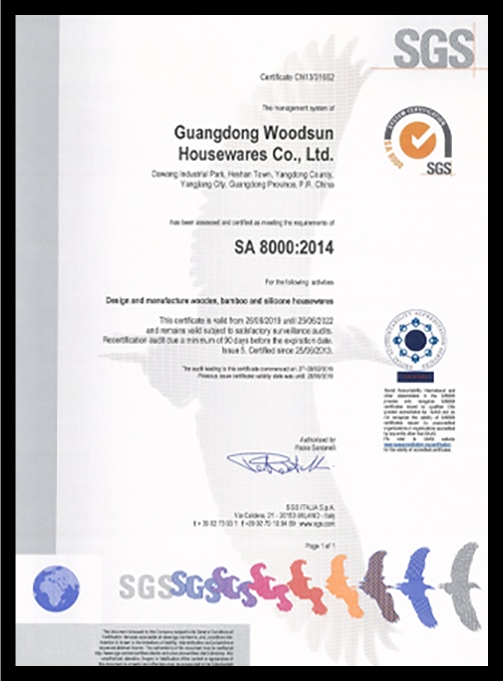

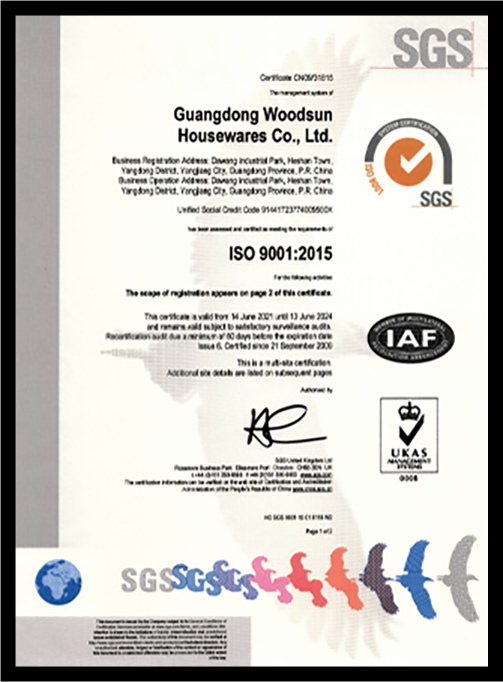

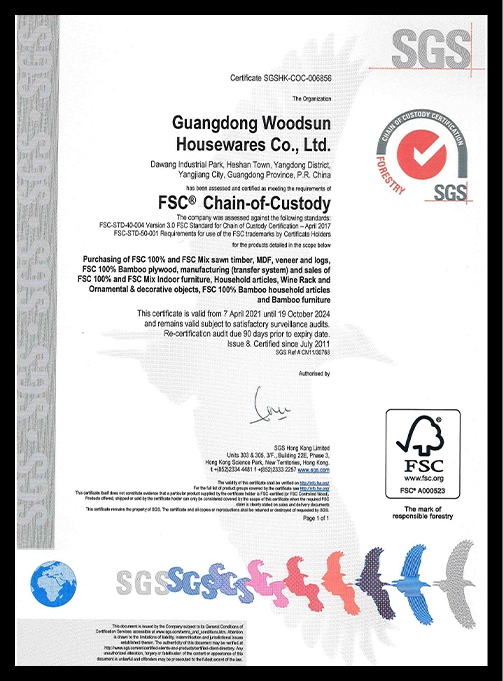

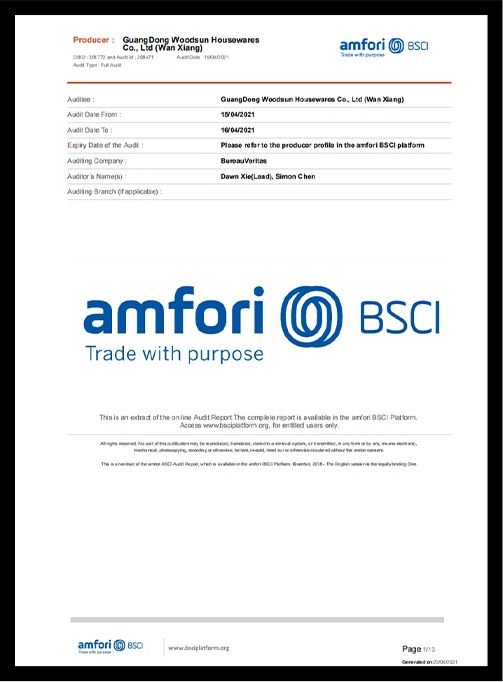

For the environment, we have installed dust collection systems, robotic machinery and sewage treatment system for being sustainable and eco-friendly. We are certified compliant with SA8000, ISO9001, ISO14001, BSCI and actively cooperate with any factory audit and inspection. WoodSun always look forward to partnering with you.

PRODUCT DEVELOPMENT

Our product development team consists of over 20 designers and 30 engineers to facilitate design concepts for our ever growing catalogues. In the team, there are more than 10 senior technicians engaged in the design and development of thermos cups, more than 30 senior technicians for molding and tooling, and more than 10 technicians specialized in product surface treatments; the types of technical talents cover 6 major professional fields of cup and pot design and development, including: Product research/development, process design, hardware mold design and manufacturing, mold design and manufacturing for plastic products, product surface treatment research/development and automation application technology.

Since the team has been established, the cup pot product development department has successfully completed the development of more than 480 cup/pot products and 450 of them have been successfully put on production and sold well all over the world. And more new products are stepping up to improve product development details. Up to now, we have 10 national invention patents and also more than 30 patents on product and mold structure, more than 200 design patents. The customized intellectual property rights for all our customers have obtained effective protection for ensuring the safety of product production and sales.

The product research and development department has a precision molding workshop with an annual production capacity of more than 200 sets of injection molds, a hardware mold workshop with an annual production capacity of more than 80 hardware cup/ pot body molds, a professional sample production team and a surface treatment team. Has successfully developed 60 kinds of surface treatment processes can meet the needs of various products and customers. We also welcome your OEM designs.

Workshop Production

Line Automation

Patents And Certifications

Major Customers

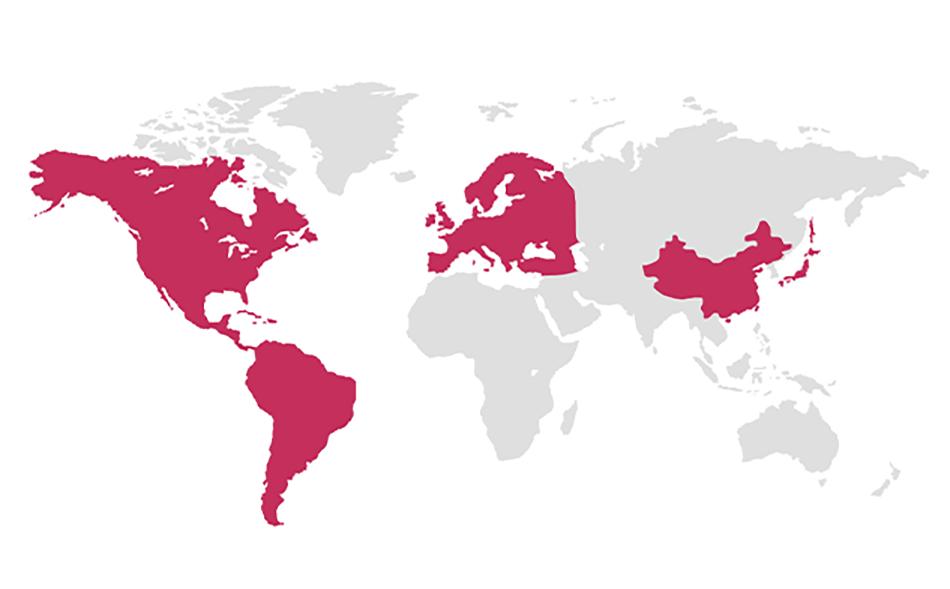

- Products are exported to the United States, Canada, Mexico, the United Kingdom, France, Germany, Japan and other countries and regions.

Exibition Hall